Technological Innovation

ROARR Energy™ invests in continuous research with our partners and developers to stay at the forefront of waste-to-energy technologies. Our commitment to innovation ensures optimal efficiency, minimal environmental impact, and cost-effective solutions for our clients. ROARR Energy™ has secured a global sales-and-marketing agreement with Technotherm, a South African engineering company, for its Pyrolysis processing. ROARR Energy™ has also secured international exclusivity for using Technotherm’s technology for all the projects in the Project Development pipeline. Due to the following critical criteria, we have selected Technotherm as a strategic technology provider. The safety and environmental protection aspects of its technologies. Their ability to produce highly desirable products with an apparent market demand. Their ability to produce these products at scale, as well as the scalability of plants.

Waste to Energy Products

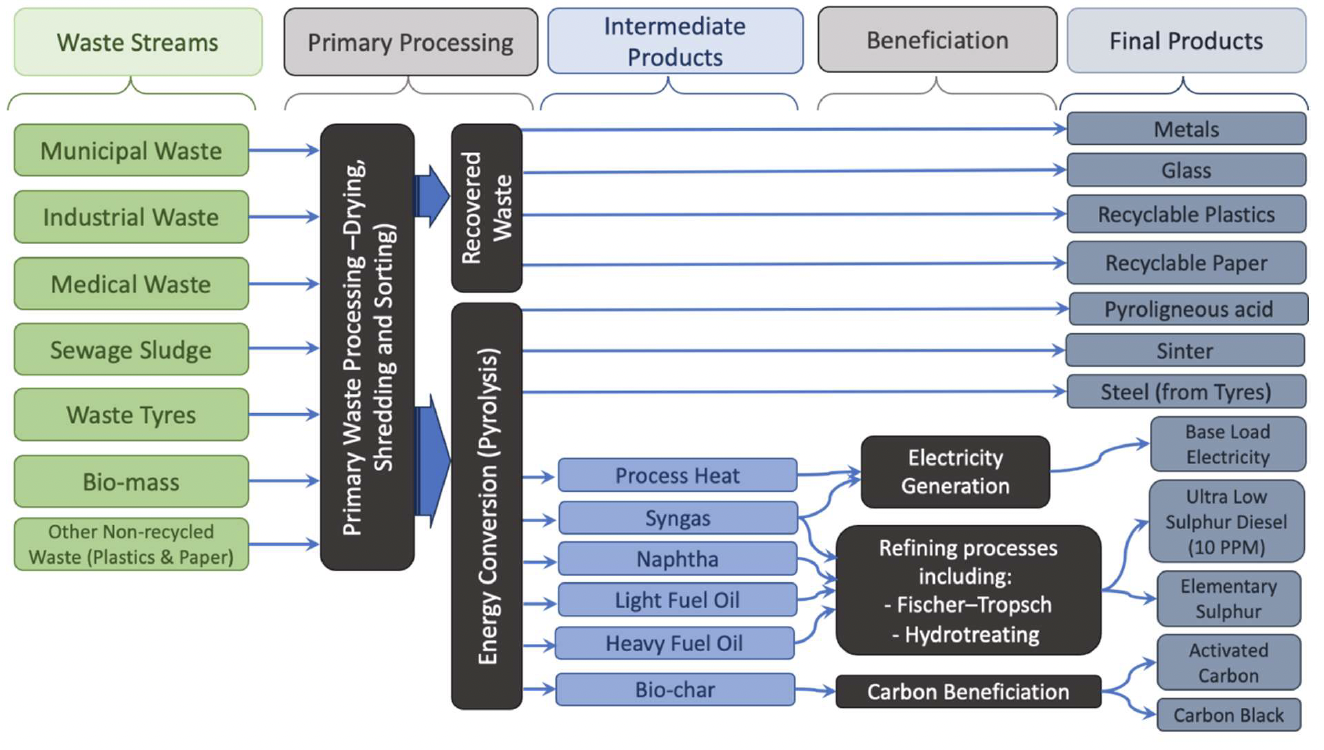

The pyrolysis process stands out for its remarkable versatility in converting various waste streams into many high-value products, demonstrating a significant stride in sustainable waste management and resource recovery. By thermally decomposing organic materials without oxygen, pyrolysis cantransform a wide range of waste materials – from biomass and plastic waste to used tires – into valuable commodities. Products such as syngas and bio-oil emerge as versatile energy sources, potentially substituting conventional fossil fuels and feeding into the chemical industry as raw materials. Biochar, another by-product, helps enhance soil health and sequester carbon, contributing to agricultural productivity and climate change mitigation. Furthermore, the refining of pyrolysis outputs broadens the spectrum of end-products. For instance, naphtha and light fuel oil distilled from pyrolysis oil serve as vital inputs in the petrochemical industry, while heavy fuel oil finds use in industrial power generation. Activated carbon, derived from refining biochar, plays a critical role in environmental remediation, and carbon black, obtained from decomposing tires, is essential in manufacturing and the rubber industries. Even niche by-products from these processes, such as wood vinegar and elementary sulphur, find applications in agriculture and industrial manufacturing. The multifaceted nature of pyrolysis, complemented by various refining processes, underscores its role in waste valorisation and reflects its alignment with the principles of circular economy, turning waste into wealth while addressing environmental concerns

Please refer to the table below for a short overview of the main products produced through our waste-to-energy technologies.

Waste Stream Processing

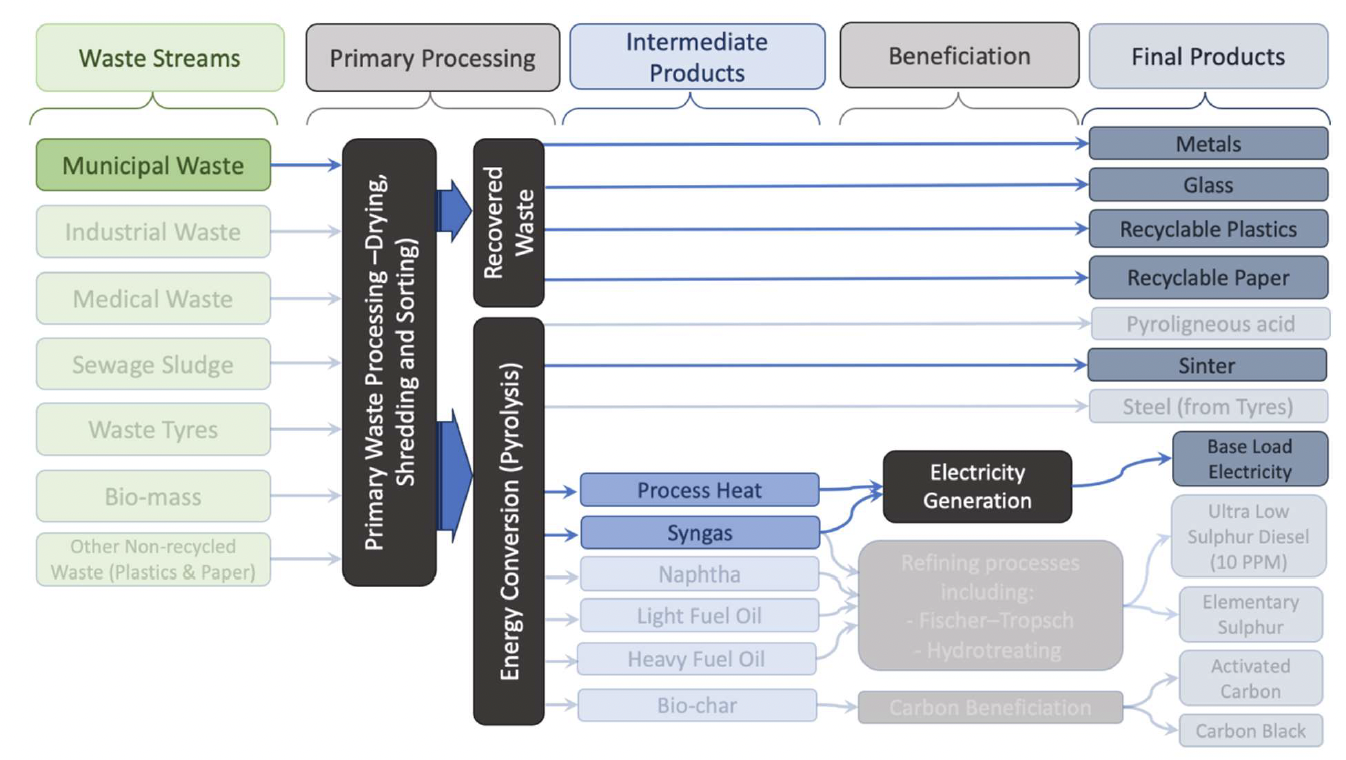

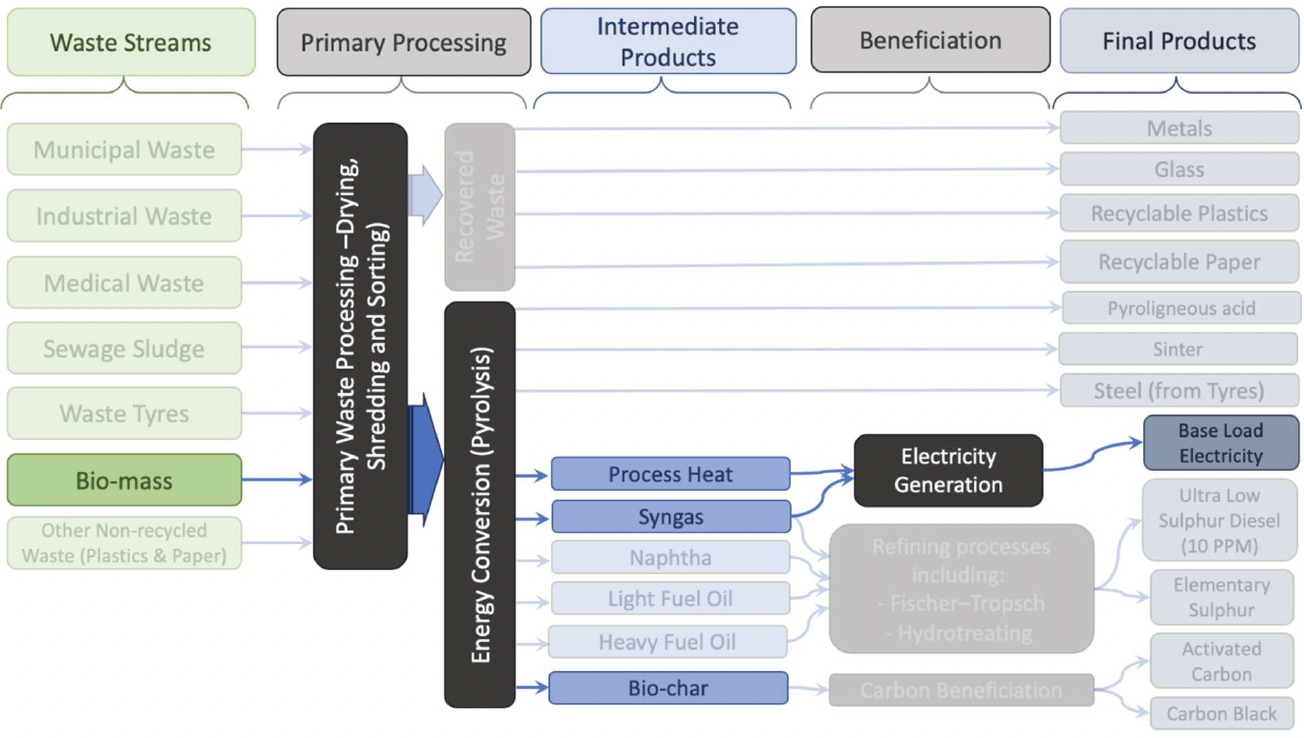

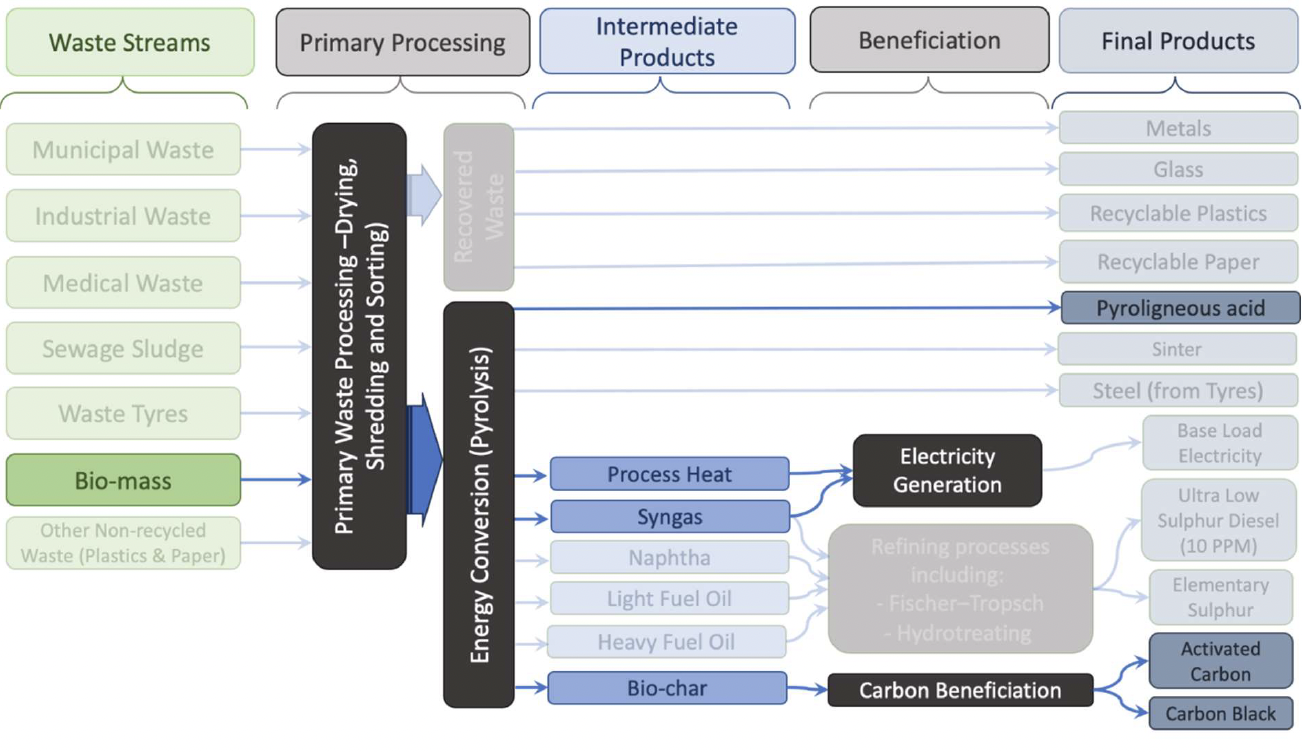

Please refer to the systems diagram below for an integrated view of the technologies and product flows of the ROARR Energy™ Waste to Energy solution.

The following sections of this document will illustrate how the major waste streams will be processed and how the financial returns will be maximised.

Municipal Waste

Municipal Solid Waste (MSW) management poses many environmental and logistical challenges. One of the primary issues is the sheer volume of waste generated, which continues to escalate with urbanisation and population growth, often outpacing the capacity of existing waste management infrastructure. This leads to overcrowding at landfills, where the decomposition of waste produces methane, a potent greenhouse gas contributing to climate change.

Additionally, landfills can be sources of leachate, a contaminated liquid that poses a significant risk to soil and groundwater quality. While reducing waste volume, the incineration of MSW can lead to air pollution, including releasing toxic substances like dioxins and furans if not adequately managed; using Pyrolysis processes essentially eliminates this risk. Another challenge is the complexity of waste composition, including a significant proportion of non-biodegradable and hazardous materials, complicating recycling and composting efforts.

Furthermore, inadequate segregation at the source results in lower recycling rates and higher contamination levels in recyclable materials. The management of MSW also encompasses social and economic dimensions, such as the need for significant investment in waste management infrastructure and services and the importance of public awareness and participation in waste reduction and recycling initiatives. These multifaceted problems highlight the necessity for integrated, sustainable waste management strategies encompassing technological innovation, policy interventions, and community engagement.

The processing of Municipal Solid Waste (MSW) through pyrolysis and subsequent refining processes offers a promising solution for waste management while generating valuable products.

Pyrolysis involves heating MSW in an oxygen-free environment, breaking the organic material into simpler compounds. The heterogeneous nature of MSW, comprising plastics, organic waste, textiles, and more, makes the process complex but also offers a diverse output range, including syngas, biooil, and biochar.

The syngas produced can be used for electricity generation or as a feedstock for chemical synthesis. Bio-oil, a liquid product, has potential as a renewable fuel or can be refined into chemicals. Biochar can be used as a soil amendment or for carbon sequestration. The main benefits of our technologies are:

Waste Volume Reduction: Pyrolysis significantly reduces the volume of MSW by up to 90%, easing the pressure on landfills and the limitations on Air Space. This is crucial in urban areas where land availability for waste disposal is limited.

Energy Recovery: The process converts waste into energy-rich products like syngas and bio-oil, providing a renewable energy source for electricity and reducing reliance on fossil fuels. For Municipalities, this also offers a risk mitigation solution for their dependence on Electricity from the National Grid.

Resource Recovery: Pyrolysis facilitates the recovery of resources from waste. Metals and inorganic materials can be separated and recycled, while organic waste is transformed into valuable by-products.

Environmental Impact: This waste processing method reduces greenhouse gas emissions compared to traditional landfilling and incineration, as it captures and utilises the energy content of the waste.

Economic Benefits: The operation of pyrolysis plants generates employment and can be economically beneficial, especially when combined with incentives for renewable energy, Electricity generation and recycling.

Versatility: Pyrolysis can handle a wide range of waste materials, making it a versatile option for different types of MSW.

Please refer to the diagram below for the processes used to process MSW and the various product

flows.

In summary, the pyrolysis of MSW, complemented by refining processes, offers an integrated solution for waste management, resource recovery, and renewable energy production. This approach aligns with sustainability principles and the circular economy, addressing environmental and economic challenges associated with waste disposal.

Municipal Waste

Utilising pyrolysis to process industrial waste offers a transformative approach to waste management and resource recovery. This process, which involves the thermal decomposition of materials in an oxygen-free environment, is particularly effective for treating a range of industrial wastes, including plastics, rubber, and certain industrial by-products.

Main Benefits:

Waste Reduction: Pyrolysis significantly reduces the volume of industrial waste. This is particularly important for materials that are not readily biodegradable or recyclable, such as certain plastics and rubber products.

Energy Recovery: One of the critical outputs of pyrolysis is syngas, a mixture of hydrogen and carbon monoxide, which can generate electricity or heat. The process sometimes produces biooil, which can be refined into various fuels or chemical products. This transformation of waste into energy contributes to resource efficiency and energy recovery.

Material Recovery: Pyrolysis can recover valuable materials from waste. For instance, carbon black recovered from the pyrolysis of used tires is reused in producing new tires and other rubber products.

Environmental Impact: By diverting waste from landfills and reducing reliance on fossil fuels, pyrolysis lowers greenhouse gas emissions. The process also helps in mitigating pollution associated with waste disposal and incineration.

Economic Benefits: Implementing pyrolysis can create new revenue streams from selling byproducts like syngas, bio-oil, and carbon black. Additionally, it can reduce the costs associated with waste disposal and treatment.

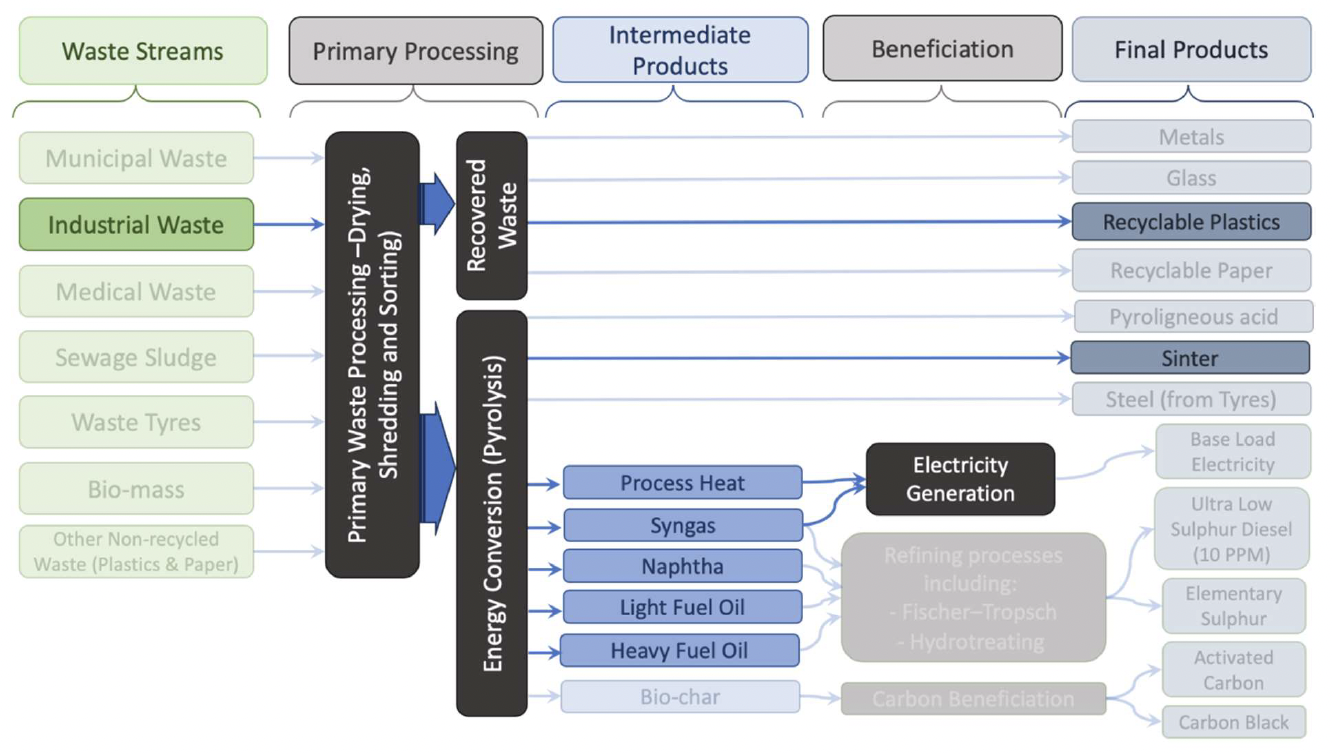

Circular Economy Alignment: Pyrolysis aligns with the principles of the circular economy by converting waste back into valuable resources, thus closing the loop and promoting sustainable industrial practices. Please refer to the diagram below for the processes used to process Industrial Waste and the various product flows.

In summary, using pyrolysis for industrial waste processing addresses the growing challenge of waste management and contributes to energy recovery, material reclamation, and environmental sustainability. It’s a technology that fits well into the broader context of sustainable industrial development and the transition towards a more circular economy. Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Sewerage Sludge

Sewerage sludge, the by-product of wastewater treatment processes, presents several challenges that complicate its management and disposal. Firstly, it contains a variety of pollutants, including heavy metals, pathogens, pharmaceutical residues, and other hazardous chemicals, which pose significant environmental and health risks if not adequately treated. Disposing of sludge in landfills or dumping in rivers and oceans can lead to soil and water contamination, adversely affecting ecosystems and potentially entering the human food chain. Additionally, as urban populations grow, the increasing volume of sewage sludge exacerbates these issues, demanding more sustainable and efficient management solutions. The use of sludge in agriculture, while beneficial for soil fertility due to its high nutrient content, raises concerns about the transfer of contaminants into crops.

Furthermore, the treatment and disposal of sewage sludge are energy-intensive and costly, contributing to the financial burden on municipal waste management systems. There’s also the public perception and acceptance issue, particularly regarding using sludge in agricultural applications, which can hinder its utilisation. Managing sewage sludge requires careful consideration of its environmental impact, health risks, and the economic costs associated with its treatment and disposal.

The application of pyrolysis to process sewage sludge represents a promising solution for waste management and resource recovery; the following benefits of using our processes include:

Volume Reduction: Pyrolysis significantly reduces the volume of sewage sludge, easing the burden on landfill sites and reducing transportation costs.

Energy Recovery: The process generates syngas and bio-oil, which can be used as renewable energy sources. This helps offset the energy consumption of wastewater treatment facilities and reduces reliance on fossil fuels.

Biochar Production: Biochar is a stable, carbon-rich product that can be used as a soil amendment. Its application improves soil health, enhances water retention, and sequesters carbon, contributing to sustainable agriculture practices and mitigating climate change.

Hazardous Material Containment: The high temperatures involved in pyrolysis can destroy pathogens and decompose toxic organic pollutants in sewage sludge, making the residual biochar safer for handling and use.

Resource Recovery: Elements like phosphorus, crucial for fertiliser production, can be recovered from the pyrolysis by-products, thus recycling valuable nutrients into the agricultural cycle.

Pollution Reduction: By providing an alternative to conventional sludge disposal methods like incineration or landfilling, pyrolysis helps reduce greenhouse gas emissions and leachate production associated with these methods.

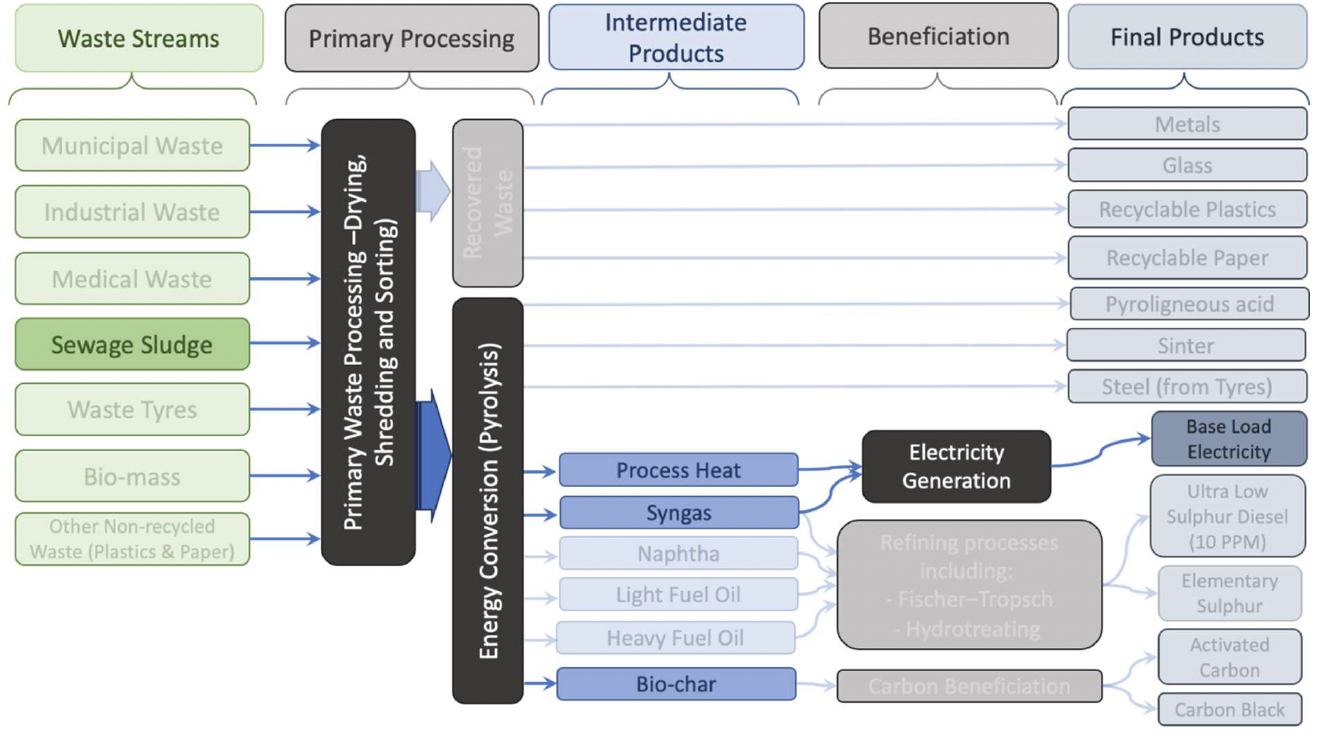

Please refer to the diagram below for the processes used to process Sewage Sludge and the various product flows.

In conclusion, the pyrolysis of sewage sludge offers a multifaceted solution, addressing waste disposal challenges and contributing to renewable energy generation, soil health improvement, andresource recovery, aligning well with sustainable waste management and circular economy principles.

Waste Tyres

Waste tyres pose significant environmental and public health challenges, primarily due to their nonbiodegradable nature and annual volume generated annually. When improperly disposed of, tyres can create unsightly stockpiles that occupy vast land areas, contributing to land and water pollution. These stockpiles are breeding grounds for mosquitoes and other vectors, leading to increased risks of diseases like dengue and Zika. Furthermore, waste tyres are highly flammable, and when they catch fire, they are difficult to extinguish, releasing toxic fumes and pollutants like carbon monoxide, volatile organic compounds (VOCs), and particulate matter into the atmosphere. These emissions can have severe health impacts, including respiratory problems, heart diseases, and cancer. Moreover, the leachate from tyre piles can contaminate soil and groundwater with harmful chemicals, including heavy metals, adversely affecting ecosystems and human health. Managing and recycling waste tyres remain daunting for many regions, necessitating sustainable and effective disposal methods such as pyrolysis and material recovery to mitigate these environmental and health risks. Using pyrolysis for processing waste tires is a promising solution for waste management and resource recovery, offering significant environmental and economic benefits.

The main Benefits of our solution include:

Waste Reduction: Pyrolysis significantly reduces the volume of waste tires, addressing a significant environmental challenge. Non-biodegradable tires pose a significant disposal problem when dumped in landfills or incinerated.

Resource Recovery: The process recovers valuable materials from waste tires. For instance, the derived bio-oil produces ultra-low sulphur Diesel. The removed sulphur is refined to Elementary sulphur. Steel recovered from the Waste Tyres is cleaned and sold. Recovered carbon is further refined as Carbon Black or Activated Carbon. Carbon black is used in various manufacturing processes, such as producing new tires or as a pigment. Activated Carbon effectively removes contaminants, thus critical in environmental clean-up. It’s used in water treatment, air purification, and chemical processing.

Environmental Benefits: Pyrolysis minimises environmental pollution by diverting tires from landfills and reducing the need for incineration. Moreover, the process itself is relatively clean, as it produces fewer pollutants compared to burning tires.

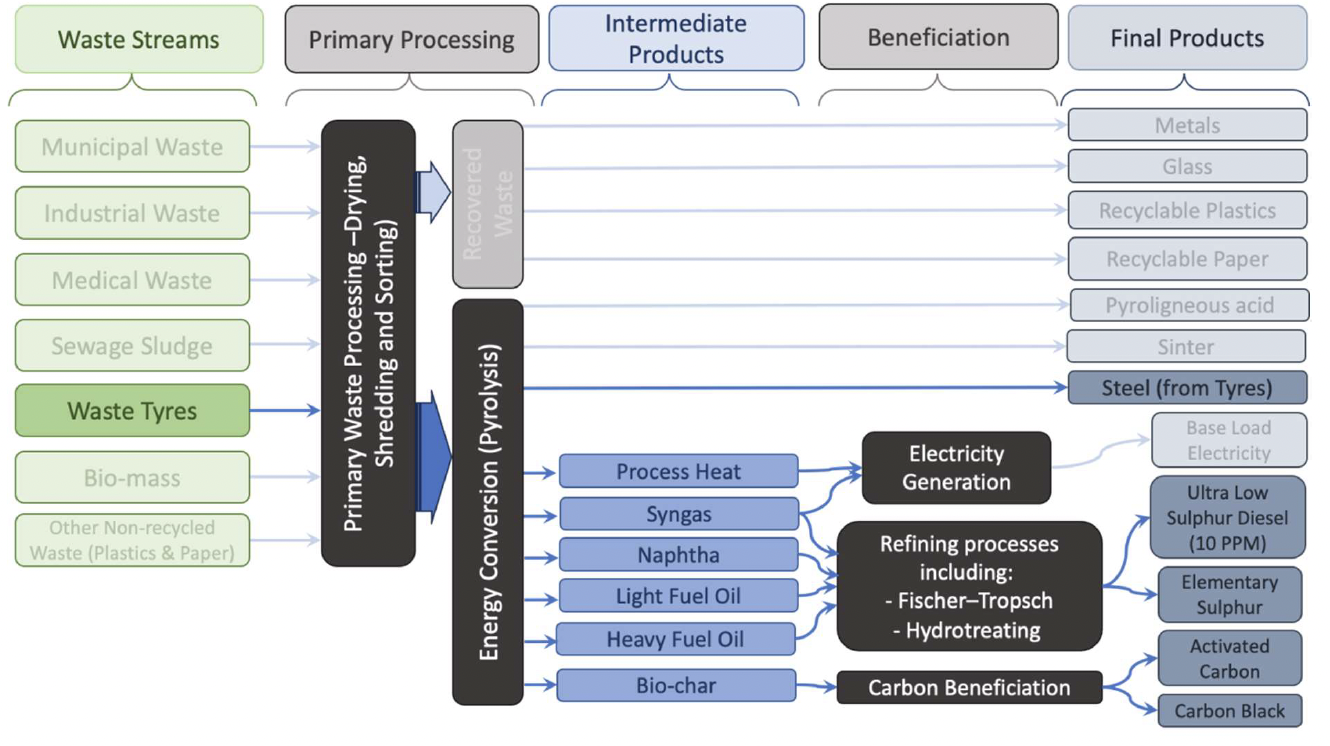

Economic Potential: The pyrolysis of waste tires presents economic opportunities through the sale of by-products and can stimulate job creation in waste processing and recycling industries. Many countries also provide grants and incentives for the processing of Waste Tyres. Please refer to the diagram below for the processes used to process Waste Tyres and the various product flows.

In summary, the pyrolysis of waste tires presents a holistic approach to tackling tire waste. It not

only aids in waste reduction but also contributes to resource and energy recovery, offering both

environmental and economic advantages.

Bio-mass optimised for Electricity Production.

Biomass refers to organic material from plants and animals, and it is a renewable energy source. It encompasses various materials, including wood and wood waste (like branches, dead trees, and wood chips), crops and their waste by-products, animal manure, and even the organic components of municipal and industrial wastes.

\

The use of biomass for energy purposes can be particularly appealing because it makes use of materials that might otherwise go to waste. Moreover, biomass is considered a renewable resource because its supply can be replenished on a human timescale, typically through the growth of plants.

When plants grow, they absorb carbon dioxide (CO2) from the atmosphere through photosynthesis, and when biomass is burned or decomposed, this CO2 is released back into the atmosphere. Ideally, this creates a closed carbon cycle with no net increase in atmospheric CO2 levels, which is beneficial for mitigating climate change compared to fossil fuels. However, the sustainability of biomass as an energy source depends heavily on how the biomass is sourced, managed, and utilised.

The utilisation of pyrolysis for processing biomass, optimised for producing electricity and process heat, represents a significant advancement in sustainable energy technology. In this process, organic biomass is thermally decomposed in an oxygen-limited environment, producing syngas, biooil, and biochar. The primary focus here is on maximising the yield of syngas, a combustible gas that can be directly used to generate electricity via gas turbines or engines.

The syngas, rich in hydrogen and carbon monoxide, serve as a versatile and efficient fuel for power generation, contributing significantly to the base load electricity supply. Additionally, the heat generated during the pyrolysis process can be captured and utilised for industrial processes, known as process heat. This dual electricity and heat production, often termed Combined Heat and Power (CHP), enhances overall energy efficiency.

The Main Benefits of the ROARR Energy™ solution are:

Renewable Energy Source: Utilizing biomass, a renewable resource, for energy production reduces dependency on fossil fuels, aligning with global sustainability goals. Waste Reduction: This process can convert agricultural residues and other organic waste into energy, thus contributing to waste management and reduction. Carbon Neutrality: Biomass is considered carbon neutral. The CO2 released during energy generation is roughly equal to the amount absorbed by the plants during their growth phase, contributing to reduced net greenhouse gas emissions.

Energy Efficiency: This process’s CHP ensures that electricity and heat are utilised, increasing the overall energy efficiency compared to conventional methods where heat is often wasted. Converting waste into energy provides an economically viable solution for managing biomass waste, which otherwise would require disposal or treatment.

Local Energy Generation: This approach can support local energy generation, reducing energy transportation costs and enhancing energy security. Versatility: The process is adaptable to various biomass feedstocks, making it suitable for different regional and local conditions.

Soil Enhancement: The by-product, biochar, can be used to improve soil fertility, further contributing to the environmental benefits of this process. Please refer to the diagram below for the processes used to process Biomass into mainly Electricity and Process Heat.

By optimising pyrolysis for electricity and process heat production from biomass, this technology not only presents a sustainable solution to energy generation but also integrates waste management with environmental conservation, marking a significant stride in the journey towards a more sustainable and energy-efficient future.

Bio-mass optimised to produce Wood Vinegar and Carbon products.

Utilising pyrolysis for processing biomass, particularly when optimised for producing wood vinegar and carbon products, presents an eco-friendly and efficient method for converting organic waste into valuable commodities. In this optimised process, biomass such as wood chips, agricultural residues, or yard waste is subjected to controlled thermal decomposition in an oxygen-limited environment. The process is fine-tuned to maximise the yield of wood vinegar, a liquid by-product rich in organic acids, phenols, and other chemicals. Wood vinegar finds extensive use in agriculture as a natural pesticide and soil conditioner, offering an environmentally friendly alternative to synthetic chemicals. Its application can enhance plant growth, improve soil health, and even help control pests. Concurrently, the process yields substantial amounts of carbon products, primarily biochar. This solid, carbon-rich material is recognised for improving soil fertility and water retention, thereby boosting agricultural productivity. Additionally, biochar is lauded for its carbon sequestration capabilities, contributing to climate change mitigation by capturing and storing atmospheric carbon in a stable form. The process may also produce other by-products like syngas and heat, which can be utilised for energy generation, further enhancing the system’s overall efficiency and sustainability. Please refer to the diagram below for the processes used to process Biomass into mainly Wood Vinegar and Carbon products.

Optimising biomass pyrolysis for wood vinegar and carbon products provides a sustainable solution for biomass waste management and significant benefits in agriculture and environmental protection. This approach aligns well with circular economy principles, turning organic waste streams into valuable products while contributing to reduced reliance on chemical fertilisers, improved soil health, and lower greenhouse gas emissions.

Typical Use Cases for Waste to Energy Processes:

Please refer to the sections below for a list of typical use cases for using the ROARR Energy™ processes to solve today’s pressing environmental and energy challenges. Although this document describes the processes in general terms, each project will be dealt with on its own, considering its unique ecological, commercial, technical, and financial considerations.

Municipalities that want to reduce their dependence on the national grid and reduce the impact of their waste management practices on the Environment.

Municipal Solid Waste (MSW) and sewage sludge, traditionally considered burdensome by-products of urban living, can be transformed into valuable energy resources through various technologies. These advancements enable local municipalities to reduce their reliance on the national electricity grid and foster sustainable, self-sufficient, and eco-friendly energy practices. Technologies like pyrolysis convert organic materials and plastics in MSW and sewage sludge into syngas, a mixture of hydrogen, carbon monoxide, and methane. Syngas can be used directly to produce electricity and heat. By employing these methods, a municipality can convert its organic waste streams into a significant energy source, decreasing its dependence on the grid.

The benefit for Local Municipalities includes:

Energy Independence: Municipalities can reduce their reliance on the national grid by generating their electricity from waste, enhancing energy security.

Economic Savings: Local energy production can reduce energy costs and hedge against fluctuating energy prices.

Sustainable Waste Management: These technologies offer sustainable solutions to waste management, reducing landfill use and associated environmental impacts.

Environmental Protection: By converting waste into energy, municipalities can lower greenhouse gas emissions compared to conventional waste disposal and fossil fuel energy production. Local Job Creation: Implementing these technologies creates jobs in the facilities’ construction, operation, and maintenance. In conclusion, by adopting these waste-to-energy technologies, local municipalities can achieve a more sustainable, economically viable, and environmentally friendly approach to waste management and energy production, moving towards greater independence from the national electricity grid.

Energy-intensive plants should be more independent of the local grid for their electricity supply and process heat requirements.

Integrating Waste-to-Energy technologies, like pyrolysis and biomass utilisation, can significantly enhance the energy independence of energy-intensive plants, allowing them to reduce reliance on local power grids for electricity and process heat requirements. Here’s an expanded look at how these technologies can be beneficial:

On-site Generation of Electricity and Heat: These plants can generate electricity on-site by converting waste materials (including industrial by-products, non-recyclable plastics, and organic waste) into energy. The syngas produced from pyrolysis can fuel generators or turbines, creating a reliable electricity source. Biomass, such as wood waste, agricultural residues, or even dedicated energy crops, can be sourced to produce electricity. This process can be particularly advantageous if the plant has biomass waste as part of its operations. Waste-to-energy and biomass systems can be integrated with Combined Heat and Power units to generate electricity and process heat from the same energy source. Combined Heat and Power systems are highly efficient, offering thermal and electrical energy that can be directly used in industrial processes.

Reduced Energy Costs and Increased Competitiveness: Utilising waste-to-energy and biomass for on-site energy generation can significantly reduce the costs of purchasing electricity and heat from external sources. This cost-saving can be crucial in improving the competitiveness of energy-intensive industries. Energy-intensive plants often require a constant, reliable energy supply. Generating their energy reduces vulnerability to grid outages, fluctuations in energy prices, and other external disruptions.

Tailored Energy Solutions: Waste-to-energy and biomass systems can be tailored to the plant’s energy needs and waste outputs. This customisation ensures that the energy generation is as efficient and effective as possible. Potential Revenue Streams: Surplus energy (electricity or heat) generated on-site can be sold back to the local grid, creating an additional revenue stream for the plant. Minimising Waste Disposal Needs: Using waste as a resource for energy production, energy-intensive plants can significantly reduce the volume of waste sent to landfills, thus lowering waste disposal costs and environmental impact.

In conclusion, adopting Waste-to-Energy, pyrolysis, and biomass utilisation technologies helps energy-intensive plants become more self-sufficient regarding their electricity and process heat requirements and offers financial, environmental, and operational benefits. These technologies represent a strategic investment in sustainability and long-term operational resilience.

Generating a return on large bodies of Bio-mass.

The valorisation of large bodies of biomass, such as sawdust and wood chips, focusing on producing high-value end products like wood vinegar and activated carbon, is a significant step towards sustainable resource management. Pyrolysis is crucial in this process, offering environmentally friendly and economically viable methods to convert biomass into valuable products. Environmental and Economic Benefits of this include: Sustainable Waste Management: These technologies provide a sustainable method for managing large volumes of biomass, reducing reliance on landfilling. Carbon Sequestration: Biochar production contributes to carbon sequestration, helping mitigate climate change. Economic Opportunities: The production of high-value products like wood vinegar and activated carbon from biomass creates new markets and economic opportunities, particularly in rural areas where biomass is abundant. Renewable Energy Source: Utilizing biomass as a feedstock contributes to renewable energy goals and reduces dependence on fossil fuels. In conclusion, using technologies like pyrolysis, large bodies of biomass can be transformed into valuable products like wood vinegar and activated carbon. This provides economic benefits and

Unlock Sustainable Energy Solutions Today

Contact ROARR Energy to explore how our cutting-edge pyrolysis technology can transform your waste into valuable energy. Schedule a consultation with our experts and discover tailored solutions for your waste management needs.